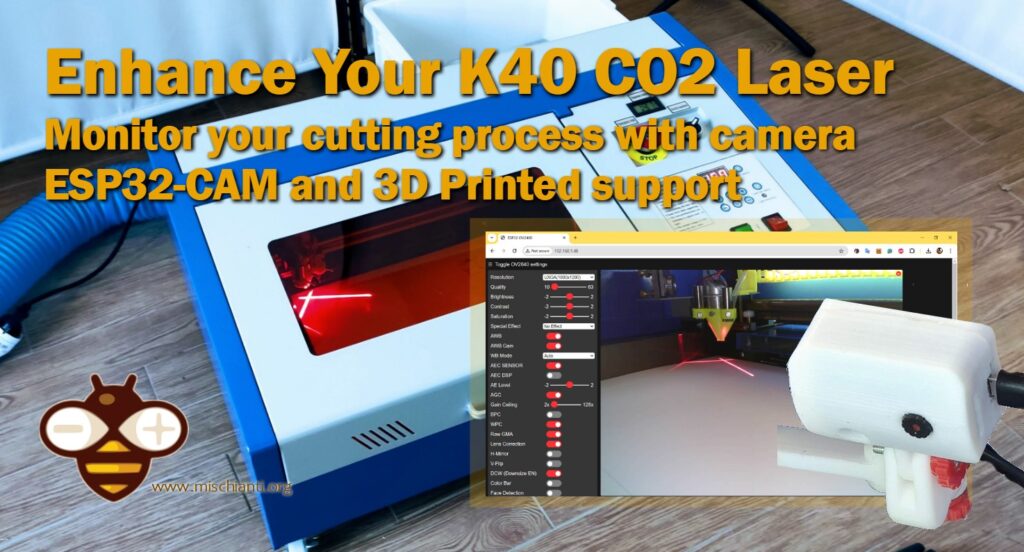

Enhance Your K40 CO2 Laser: ESP32-CAM with 3D printed case to monitor your device

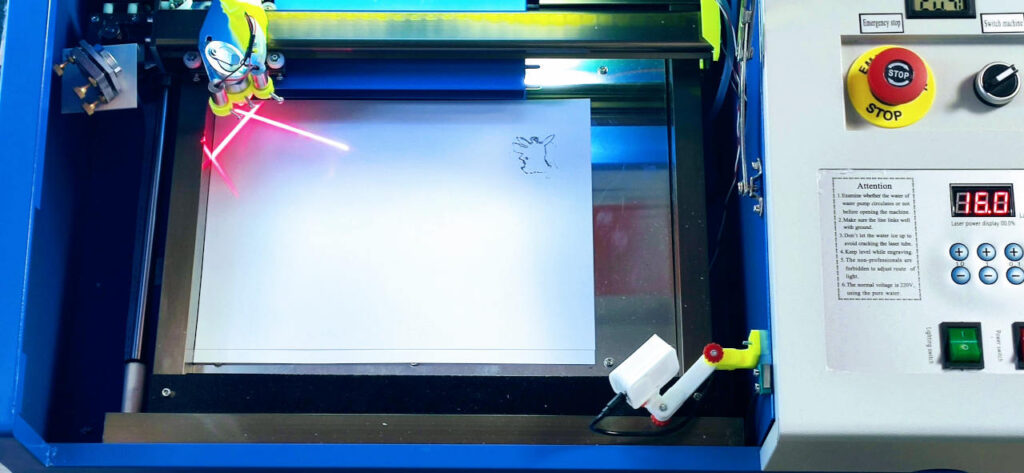

The K40 CO2 laser cutter is a remarkably popular tool among hobbyists and small businesses for its affordability and the ease with which it can be customized. One of the most valuable upgrades is the integration of a camera system to monitor and control the cutting process. This article provides a detailed account of how I upgraded my K40 laser cutter with an ESP32-CAM, including the development of a custom holder, enclosure, and firmware.

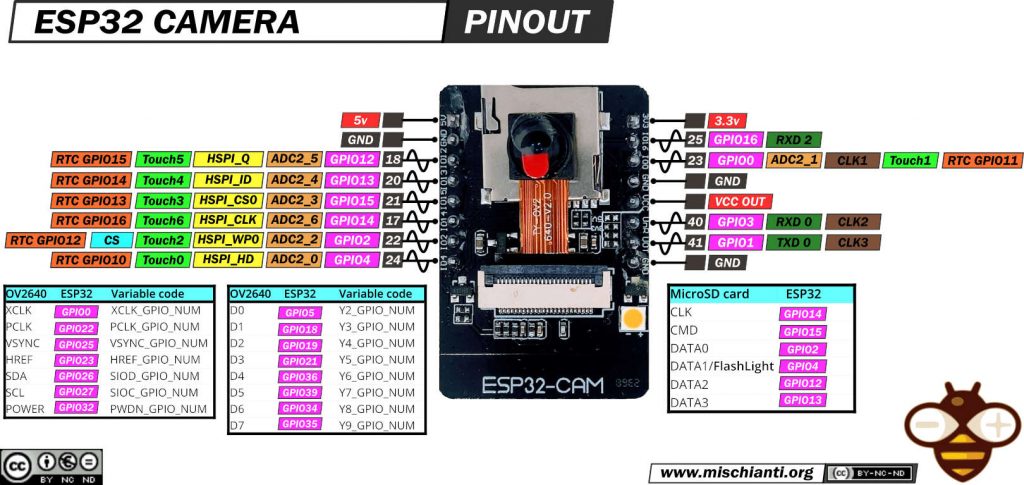

Introduction to the ESP32-CAM

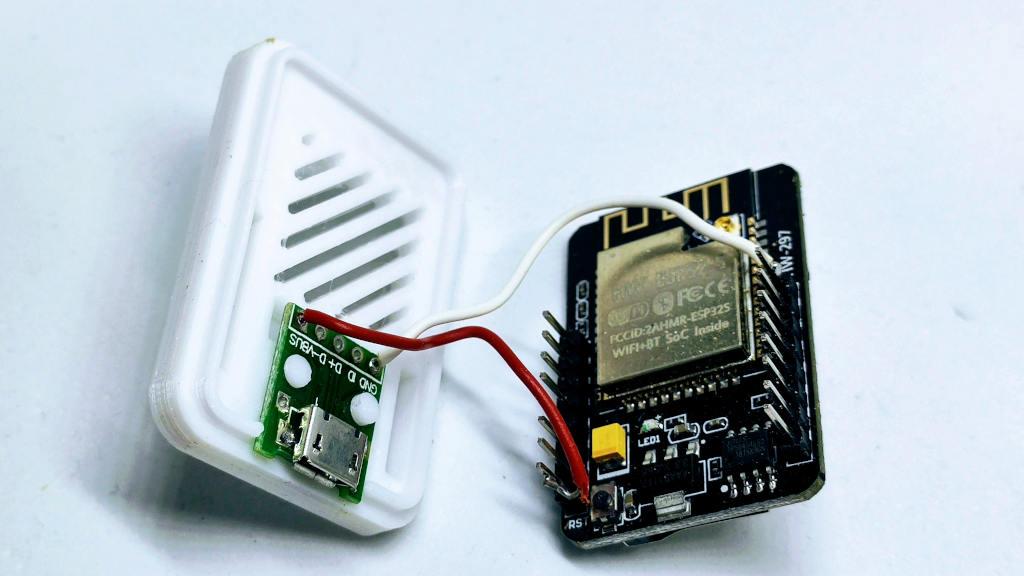

The ESP32-CAM is a small-sized camera module that integrates an ESP32-S chip and a 2MP camera. It is highly adaptable and comes at a low cost, making it ideal for DIY projects like this one. The module not only captures video but also supports Wi-Fi, which allows it to send the captured video for real-time viewing and control operations remotely.

Here where to buy the low cost esp32-cam AliExpress ESP32-CAM programmer - AliExpress ESP32-CAM bundle

Designing the Custom Holder and Enclosure

Holder Design: The first step in the integration was to design a custom holder for the ESP32-CAM that would fit into the K40’s existing structure without obstructing the machine’s operational components. Using CAD software, I designed a holder that would securely position the camera at an optimal angle to capture the entire working area of the laser cutter. The holder was designed to be easily removable for maintenance or adjustments.

Enclosure Design: The ESP32-CAM needed protection from the harsh environment inside the laser cutter, which often contains dust and debris from the materials being cut. I designed a small, ventilated enclosure using 3D printing technology, which not only protected the camera from debris but also prevented overheating. The enclosure included a clear acrylic window to ensure the camera’s view was unobstructed.

I use the same design already presented, but I’m going to create a specified holder for K40.

Developing Custom Firmware

The next major task was developing custom firmware for the ESP32-CAM. The firmware was designed to handle some functionalities. You can follow all the instructions in this article. I also upgraded the standard firmware with the possibility of powering on the flash led to prevent low visibility in low light.

All files to be printed

Here is the list of all files to be printed to obtain the needed result.

ESP32-Cam housing

ESP32-Cam rear of the housing

Assembly

You can find ESP32-CAM It here on ESP32 Dev Kit v1 - TTGO T-Display 1.14 ESP32 - NodeMCU V3 V2 ESP8266 - NodeMCU ESP-32S - WeMos Lolin32 - WeMos Lolin32 mini - ESP32-CAM programmer - ESP32-CAM bundle - ESP32-WROOM-32 - ESP32-S - ESP32-WROOM-32 - ESP32 2.8 Inch Touch ESP32-2432S028

To make the external connection, you need to use a micro-USB to dip adapter

You can find the USB adapter here AliExpress

And here is the result

The other additional elements are to be printed for the K40 specified mount.

50mm arm

Curve 90 male reversed

Mini M3 screw knob

You have to screw in an M3 screw firmly, and that’s it.

You can find the screw on Aliexpress Countersunk Head Screw - Aliexpress Pan Head Screw - Aliexpress nut

K40 mount

Here is the specified mount for the camera to adapt to the hole in the case of K40.

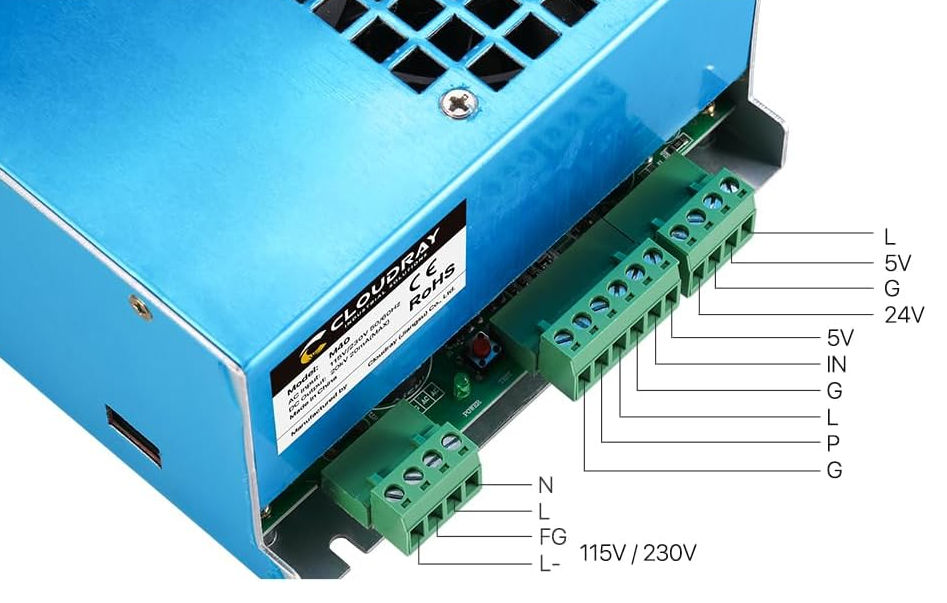

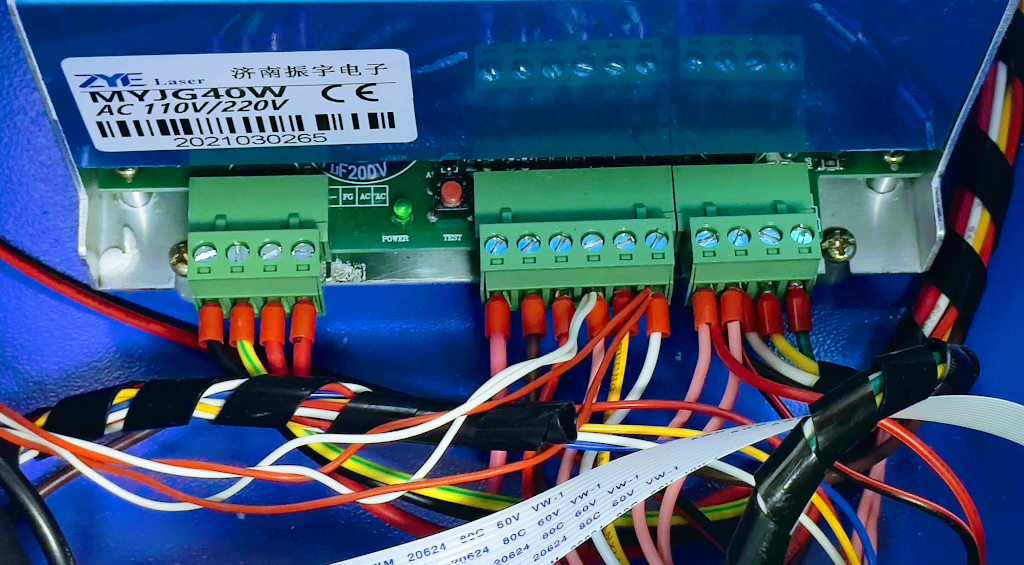

Power the camera

The camera uses a micro USB adapter, which works at 5V; the power supply of K40 has a 5V output and can be adapted to power the camera.

Remember, the 5V output can provide up to 500mA of current. Ensuring you do not exceed this limit is crucial to avoid overloading the circuit. This careful setup will power the laser diode effectively, allowing it to be a precise guide for your laser-cutting projects.

I use a USB adapter like this.

Here the adapter USB Male connector socket USB female connector socket

Installing the Camera System

With the holder and enclosure ready and the firmware developed, the next step was installing the ESP32-CAM system into the K40 laser cutter. The installation process involved the following steps:

- Mounting the Holder: The holder was fixed inside the laser cutter, ensuring that the camera had a clear view of the entire cutting area.

- Connecting to Power: The ESP32-CAM was connected to the K40’s power supply, ensuring it had a stable power source without interfering with the machine’s operations.

- Network Setup: The ESP32-CAM was configured to connect to the local Wi-Fi network. This setup was crucial for remote monitoring and control capabilities.

- Final Testing: After installation, extensive testing was conducted to ensure that the video streaming was stable and that the camera could reliably control the laser cutter through the new firmware.

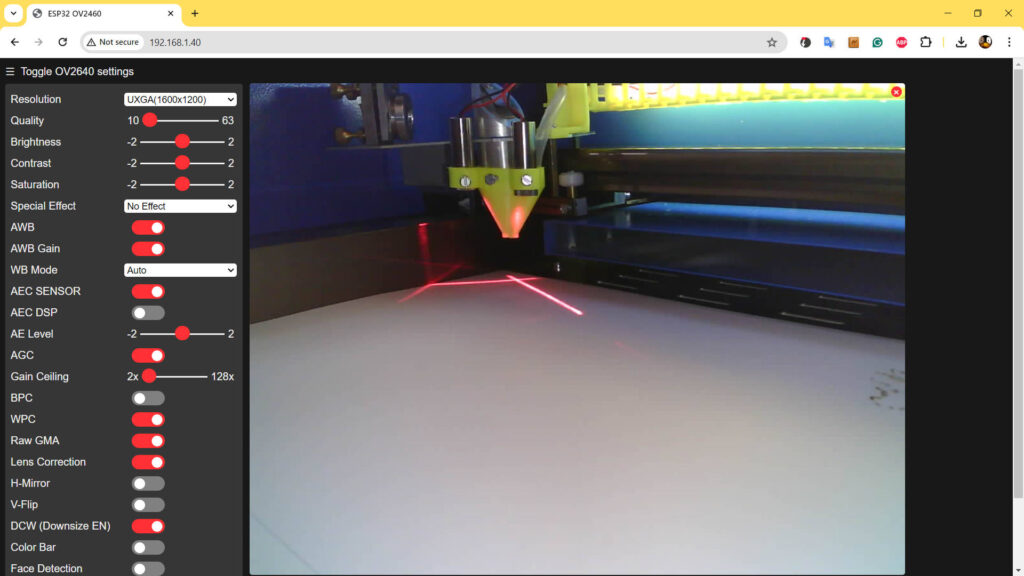

After doing all the steps now, you can control the laser from your browser, and It’s very useful.

Thanks

Upgrading the K40 laser cutter with an ESP32-CAM has significantly enhanced its functionality, allowing for real-time monitoring and remote operation. This addition is not just a technical enhancement but also a practical upgrade that increases safety and efficiency. This upgrade is a testament to the possibilities that open up when technology is applied creatively in DIY projects.

- K40 40w CO2 Laser cutter engraver: review, first usage, and upgrades (all you need to know)

- Using Inkscape and K40 Whisperer for Cutting and Engraving with a K40 CO2 Laser

- Enhance Your K40 CO2 Laser: 3d printed nozzle head with air assist and laser crosshairs

- Enhance Your K40 CO2 Laser: ESP32-CAM with 3D printed case to monitor your device